Custom and Special Technical Articles in Rubber

MGV specializes in the design, production, and molding of custom rubber technical articles and special products tailored to meet unique customer requirements.

Design and Production: Compounds and Vulcanization

Compounds

At MGV, we source high-quality rubber compounds from top European suppliers to produce custom molded rubber products that comply with client-specific technical specifications. Available compounds include SBR, NR, NBR, HNBR, EPDM, CR, ACM, VMQ (silicone), and FKM (Viton). These materials can meet various regulatory standards, such as those for gas, potable water, and automotive applications. Frequently used compounds include:

- NBR (Nitrile Rubber): Ideal for contact with oils, hydrocarbons, and water, with a temperature range of -40ºC to +110ºC.

- FPM (Fluorinated Rubber): Suitable for high-temperature applications, resisting up to 200ºC, commonly used for O-rings exposed to oils and fuels.FPM - Gomma Fluorata.

- EPDM (Ethylene Propylene Rubber): Perfect for seals that come into contact with water and steam, withstanding temperatures from -50ºC to +150ºC. withstanding temperatures from -50ºC to +150ºC.

Rubber Vulcanization

Rubber vulcanization is a critical process that improves elasticity and abrasion resistance, ensuring durability under stress.

This process, involving physical and chemical changes, results in high-quality rubber products capable of withstanding wear, fatigue, and harsh environmental conditions. Quality tests, including hardness verification in ShA or mIRHD depending on the product’s geometry, are performed on all vulcanized items to ensure proper vulcanization. The values are recorded to maintain batch traceability and for any future inspections. These vulcanized rubber products are suitable for various industries, including industrial, automotive, and heavy equipment. Upon request, additional tests can be conducted to verify mechanical properties or simulate aging for specific batches.

Rubber Production and Molding

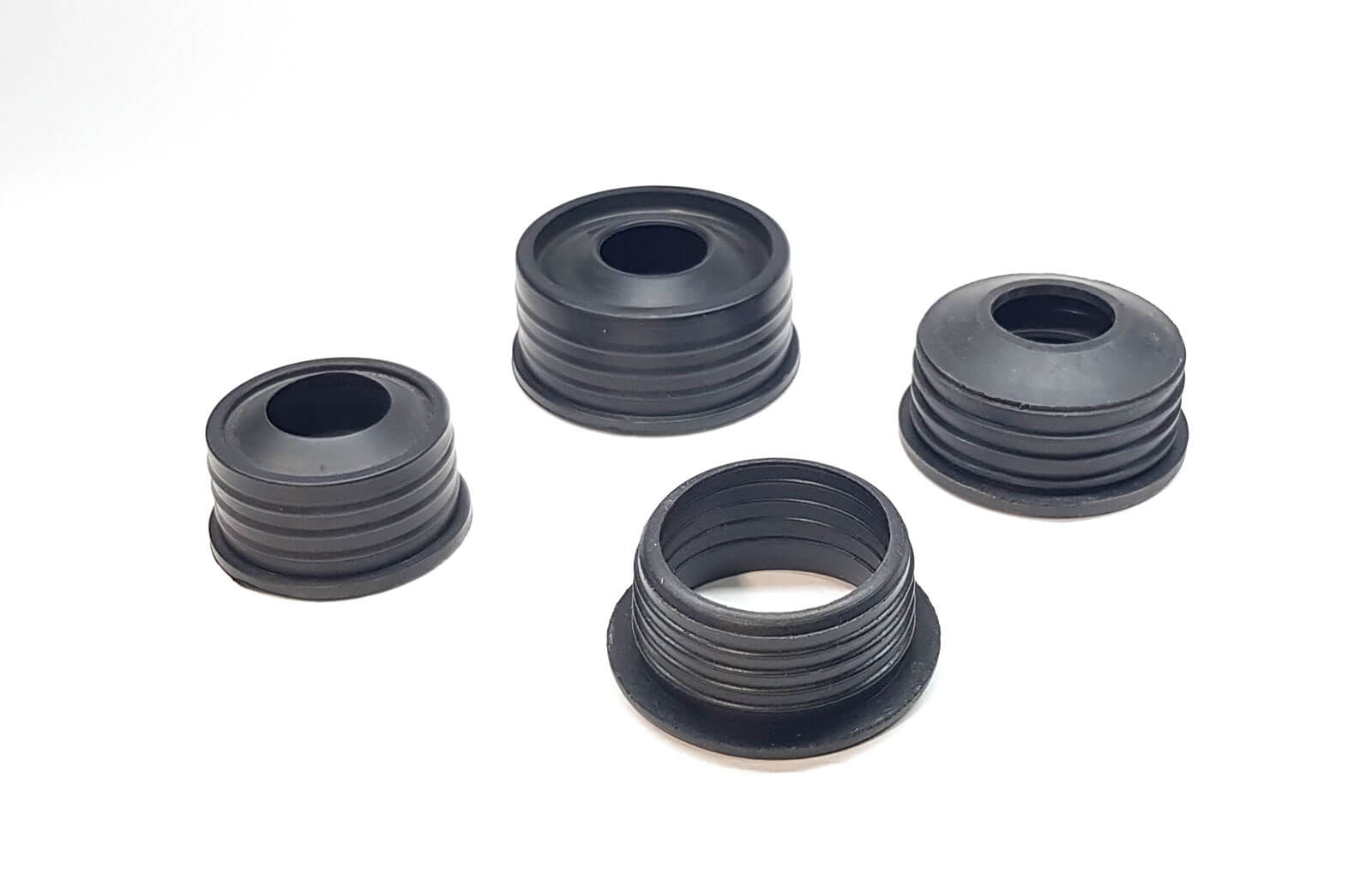

Selecting the appropriate materials and designing custom rubber parts require an analysis of factors such as temperature, pressure, fluid type, and material compatibility. In MGV Rubber meets customer needs by designing products with the right properties and compounds before proceeding with molding. This ensures that custom rubber seals, bushings and other components are made to exact specifications.

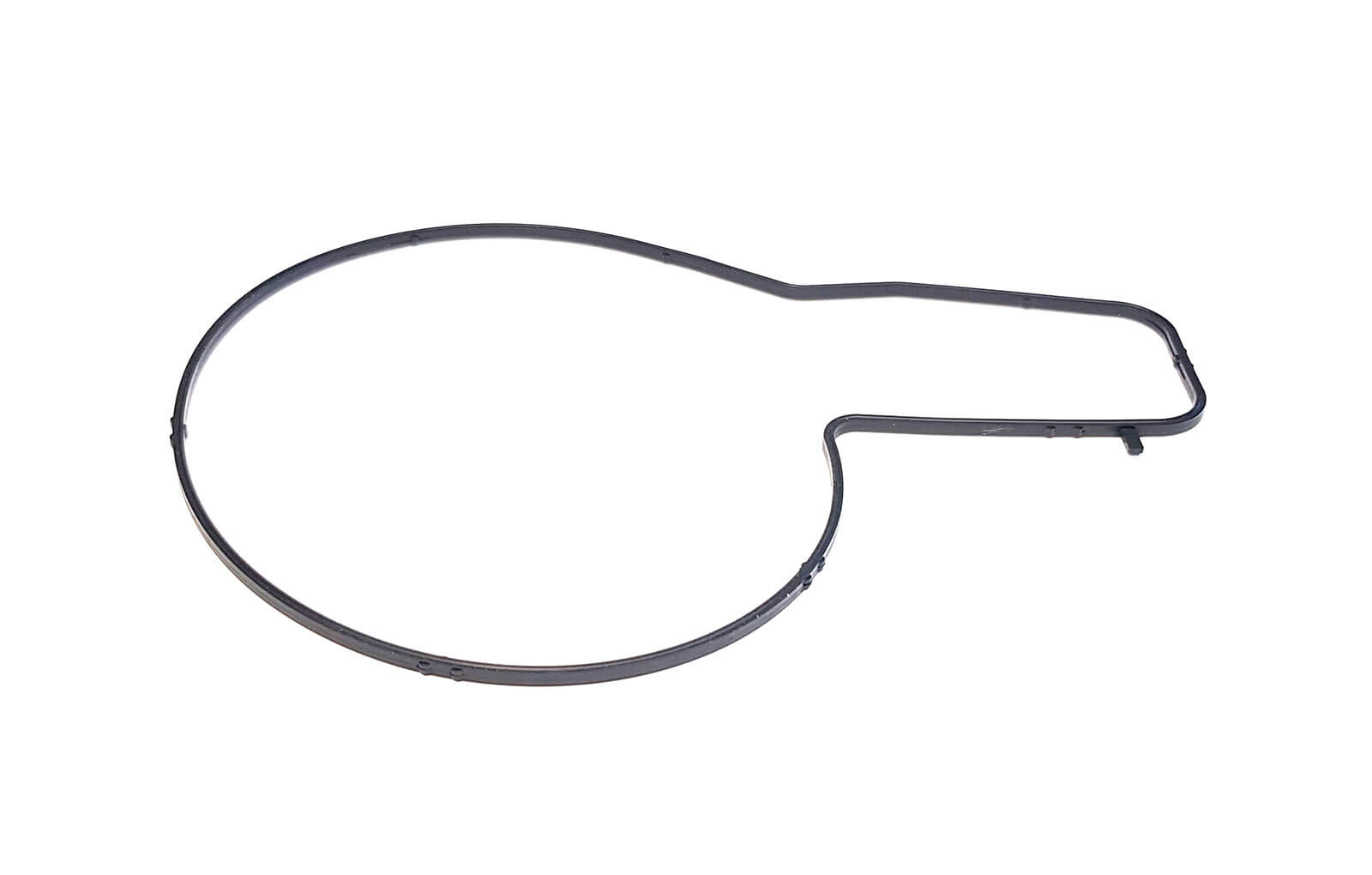

Custom Rubber Technical Articles

MGV Rubber produces a wide range of rubber technical articles for various sectors, including automotive, medical, food, home appliance, and general industrial applications.

Custom Rubber Products Designed on Request

MGV excels in custom rubber molding service, offering tailored solutions across multiple industries. Clients can request bespoke rubber articles through a very collaborative consultation service that guides them on the material selection and into the production process world. We ensure the most suitable finishes, such as Teflon coating or chrome plating, to optimize product performance. All items are manufactured in-house, undergo rigorous quality control, and are meticulously packaged for global distribution.All products undergo strict quality control and are meticulously packaged for worldwide delivery.

Quality

At MGV, quality is not just about the final product, but it is also a good customer service which is a must for us. Consistent quality checks are in place to ensure that all products meet the highest standards. Our commitment to quality is reflected in our certification to UNI EN ISO 9001:2015, which guarantees the quality of the entire production process and represents our dedication to continuous improvement and organizational optimization.

Certificate UNI EN ISO 9001:2015

Type of articles

- Custom-designed seals