Research and development

Rubber Products and Components Design

MGV focuses on designing custom rubber technical articles tailored to specific needs, which are subsequently produced in series. The main stages of rubber product design include:

- Client Kick-off: The MGV Rubber technical team collaborates closely with the client to devise the ideal rubber component solution that meets both the client’s requirements and the application’s specifications.

- Prototyping: Before mass production begins, a prototype is created based on the technical drawings provided by the client. This step is crucial for testing the product and assessing any necessary modifications.

- Molding: Once the prototype is validated, custom molds are designed and manufactured for the series production of the product.

The Different Stages of Production and Molding of a Rubber Component

The production process of rubber technical articles starts with 3D design of the component, which leads to the production of a prototype. This prototype is essential for validating the project, testing it, and making any adjustments until a final product is achieved, allowing for definitive production to commence. The sample prototype can be produced using rapid 3D prototyping with special resins or, for more accurate sealing tests, by constructing a pilot mold made of steel specifically for the required application and design. Once the prototyping phase is complete, the series production of rubber products can begin.

Rubber Molding

MGV specializes in the molding of rubber technical articles tailored to quality standards. Rubber is a versatile material widely used across various industries, including mechanical and medical sectors, thanks to its elastic properties and resistance to extreme temperatures.

Production and Moulding of a Rubber Component or Product

The production process for rubber technical articles begins with 3D design of the component, allowing for the creation of a prototype that validates the project, tests its functionality, and makes any necessary modifications before initiating mass production. In the design phase, we incorporate 3D printing using FDM or vacuum casting techniques, ensuring precision and adaptability. Once the prototyping phase is complete and approved, we can start the series production of the rubber products.

Rubber Processing: Molding

Upon approval of the prototype, we move into the molding phase for both the rubber and the product using the mold created during prototyping. The rubber molding process can be executed via injection or compression methods.

Injection Molding: MGV Rubber’s Machinery

MGV’s machinery park features automatic horizontal and vertical injection presses to minimize production costs while enhancing competitiveness. We switch vertical injection presses for larger and heavier products and compression presses for smaller batches with better quality-to-price ratios. Molds can range from 200×200 mm to 700×800 mm, requiring closure forces between 150 and 450 tons. Quality control is conducted either through sampling or 100% inspection based on specific requirements. The presence of a sorting machine allows for semi-automated operations, increasing productivity and reducing potential operator errors. For more critical components or higher-volume batches, MGV chooses an optical non-contact measuring machines to detect defects, ensuring precise quality assurance.

Molding of Technical and Industrial Rubber Products

MGV’s molding of technical rubber articles includes hundreds of projects. Often, the majority of produced components are part of larger projects for which we also develop design and CAD 3D planning side by side with our clients. Quality production must have effective design; therefore, MGV oversees the entire process from the idea to the design, from prototyping to molding, ending with the series production.

MGV supervise the whole process, from idea to design, from prototyping to stamping, up to mass production. The technical department designs the molds and equipments necessary for manufacturing, employing state-of-the-art tools such as multi-axis CNC centers and electrical discharge machining (EDM). We carefully select the most suitable materials and consider appropriate surface finishes for each application, such as Teflon coating and thick hard chrome plating. Depending on the raw material, thermal treatments may be necessary to prevent premature mold wear, particularly for highly abrasive compounds, while chrome plating is chosen to improve part release from the mold. Products manufactured at MGV undergo rigorous quality control and are carefully packed for shipping worldwide. The range of MGV products includes sleeves, seals, bellows, membranes, plugs, and frames. We also specialize in rubber-metal components, producing custom designs for silent blocks, supports, anti-vibration mounts, buffers, and suction cups. Furthermore, MGV has substantial experience in co-molding rubber and PTFE, as well as supplying assembled rubber and plastic parts.

Rubber Compounds for Design and Production of Industrial Products

MGV offers design, manufacturing, and molding services for both custom and standard rubber technical articles. When developing your product, you can collaborate with our technical office to select the most suitable type of rubber compound for your technical article. Factors to consider when choosing the right rubber compound include operating temperature, pressure, type of contact fluid, required deformations, and mechanical loads, as well as the specific industry of application.

Design and Production: Compounds and Vulcanization

At MGV Rubber, we source rubber compounds from leading European suppliers to create customized articles based on specific customer requirements. We work with a variety of compounds, including SBR, NR, NBR, HNBR, EPDM, CR, ACM, AEM, VMQ (Silicone), and FKM (Viton). All types of rubber compounds can be supplied according to various standards, including those for gas, potable water, food-grade applications, and automotive use. For detailed information, you can consult the complete table of rubber compounds used at MGV Rubber here.

Choosing the Right Rubber Compounds

Choosing the correct rubber compound for your application and industry type is crucial to prevent malfunction or premature wear of seals and, consequently, the application itself. This is why the MGV Rubber team will assist you during the selection of the most suitable compound for producing the rubber technical article that best fits your needs and application requirements. There isn’t a universally superior polymer; rather, the best polymer is the one that fits a specific application.

Industrial and Technical Rubber and Silicone Products Custom Made

MGV specializes in designing, manufacturing, and molding custom-made technical rubber products to meet the specific needs of various industries.

Rubber Properties

The primary feature of rubber is its elastic recovery, also known as elasticity. Rubber materials, or elastomers, can be stretched far beyond their original length and will return to their initial shape without breaking. These elastomers vary in characteristics depending on the type of polymer, but most offer high impermeability to water and air, as well as resistance to abrasion and tension. Some rubber compounds withstand temperatures exceeding 200°C and remain unaffected by harsh chemicals, while others maintain elasticity even at extremely low temperatures, down to -100°C.

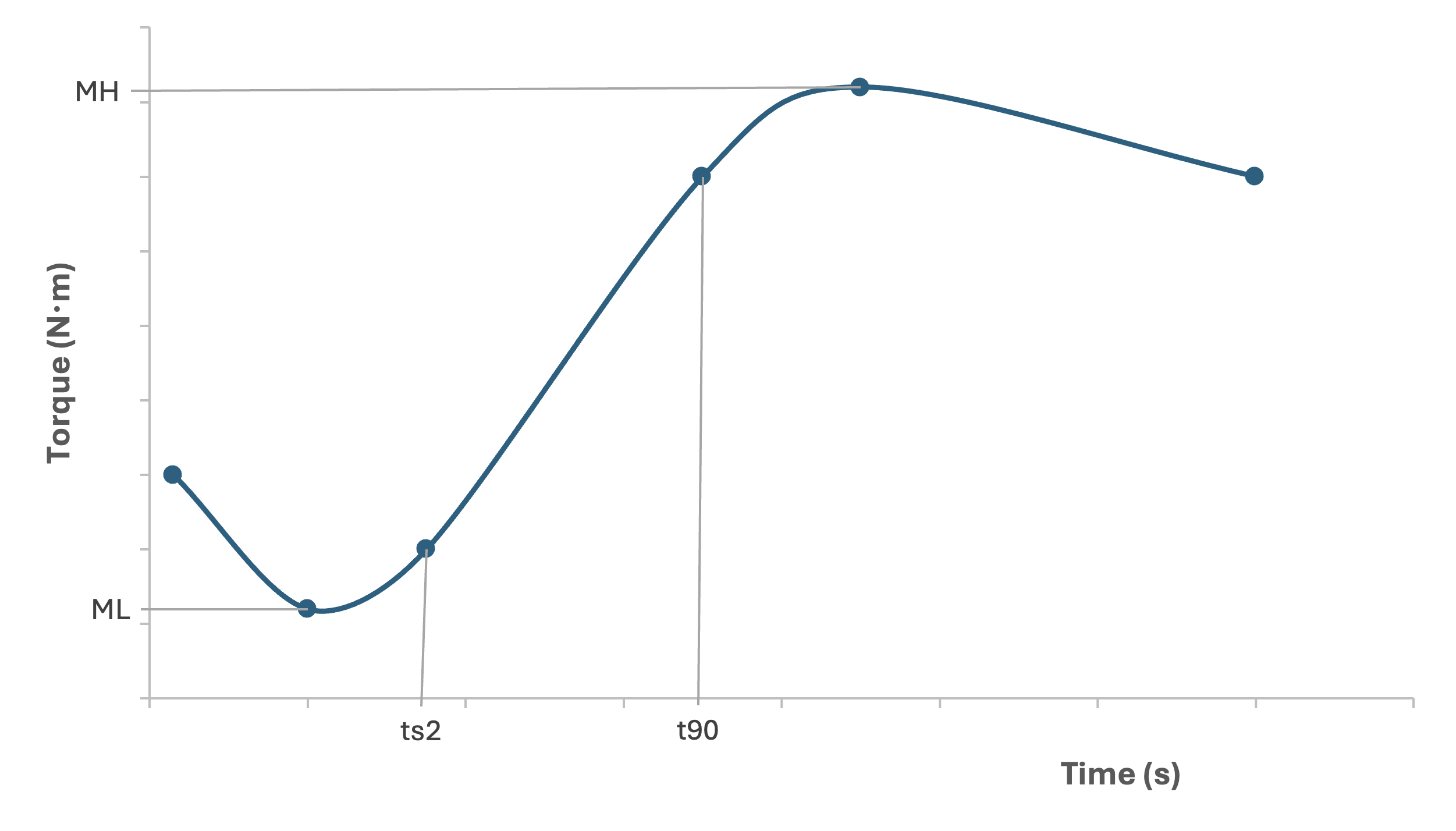

The rheometric curve illustrates the compound’s behavior during cross-linking and processing, providing detailed information about the properties of the final molded product. Key parameters include:

- Minimum Torque (ML): Indicates the compound's viscosity at a given temperature before vulcanization begins.

- Induction Time. The period from the start of the rheometric test to the moment the torque increases by 2 units, providing scorch time information.

- T90: The optimal time for cross-linking, representing the interval until 90% of the maximum torque (MH) is reached.

- Maximum Torque (MH). Reflects the stiffness of the fully vulcanized rubber compound at a fixed temperature.

Design and Fabrication: Compounds, Vulcanization, and Hardness

In MGV acquistiamo le mescole dai migliori produttori Europei per la realizzazione di articoli a disegno, seguendo specifiche tecniche del singolo cliente: SBR, NR, NBR, HNBR, EPDM, CR, ACM, AEM, VMQ (SILICONE), FKM (VITON). Tutti i tipi di mescola possono essere forniti conformi a diversi capitolati, tra cui gas, acqua potabile, alimentare, automotive.

Rubber Vulcanization

Rubber vulcanization enhances the compound’s elasticity, abrasion resistance, and mechanical durability, making it suitable for producing high-quality rubber items. After undergoing a physical-chemical vulcanization process, quality and strength tests ensure that the rubber’s properties are preserved in the final product. Vulcanized rubber products are ideal for industrial, automotive, earth-moving machinery, and other demanding applications.

Rubber Hardness

Rubber hardness is typically measured in Shore units, which assess the material’s resistance to penetration or indentation. According to ASTM D 2240-00, there are approximately 12 Shore scales, differentiated by the material’s hardness and the applied force. The Shore A scale is commonly used for medium-soft elastomers and rubbers, while the Shore D scale measures harder plastics. For thinner parts, the micro IRHD scale is used to accurately test even very thin items. Per i particolari più piccoli, di basso spessore, si utilizza invece la scala micro IRHD, facendo uso di un apposito strumento in grado di testare anche articoli molto sottili.

Custom Silicone Mouldings

Silicone rubber is gaining popularity due to its outstanding elasticity, high-temperature resistance, and durability against weather conditions. Silicone moldings are widely used across industries such as automotive, food, medical, and mechanical. Additional benefits of silicone rubber include impact resistance, low-temperature flexibility, resistance to bacteria, fungi, chemicals, and radiation, as well as being odorless and tasteless.

MGV Rubber conducts regular inspections to ensure that all production meets the highest standards. The commitment to quality, reliability, and thorough quality control distinguishes MGV’s operational methods, aiming to provide customers with the best available products on the market.

Quality Assurance

MGV conducts continuous quality checks to ensure compliance with the most stringent standards. Quality, reliability, and thorough inspections are integral to our work, and we aim to provide the highest quality products available. As MGV srl bases its success on continually meeting the expressed and implied expectations of its clients, the following strategic priorities have been established:

- The quality of products

- The quality of products

- Adherence to delivery timelines

- Technical assistance for customers and suppliers

Ensuring quality is fundamental, and all personnel are trained towards meeting the requests and expectations of our clients. o achieve these goals, management aims to maintain a robust Quality Management System in line with the established objectives and the UNI EN ISO 9001-2015 standard. This system serves to:

- Play a critical role in the decision-making processes at MGV

- Clearly define the duties and responsibilities of all personnel

- Provide a tool for guaranteeing transparency to clients

Management is fully convinced that applying this policy requires deep involvement and accountability from all employees. Therefore, implementing the Quality Management System is a commitment wholeheartedly embraced by the leadership team. Management reviews progress and improvement activities at least annually during the Management Review meeting, setting objectives and indicators. These indicators are measured through the analysis of Commercial, Production, and Organizational activities, as well as Customer Satisfaction and Internal Inspection Verifications, allowing for the continuous assessment of the Quality Management System’s performance. The competitive landscape in which the company operates is intense. However, the local environment known as Rubber Valley allows for cost optimization and resource excellence. Since rubber is not a recyclable material, its processing generates harmful fumes. MGV continuously utilizes and upgrades equipment and facilities to minimize these emissions while fully respecting both the environment and worker safety. It is crucial to emphasize that particular attention is given to workplace safety, employee training and information, and the development of policies that position MGV as a model for environmental protection and sustainability within the industry.